R & D

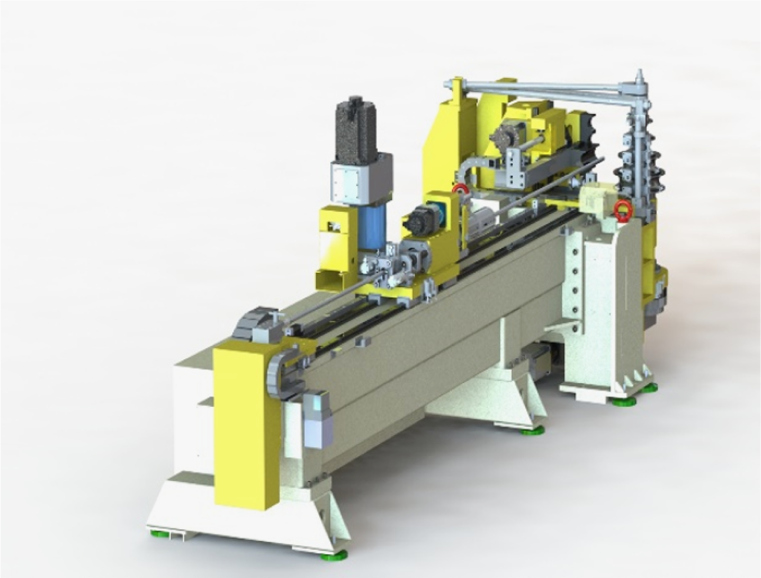

ECO CNC offers total solutions for automated lines involving pipes

Research field

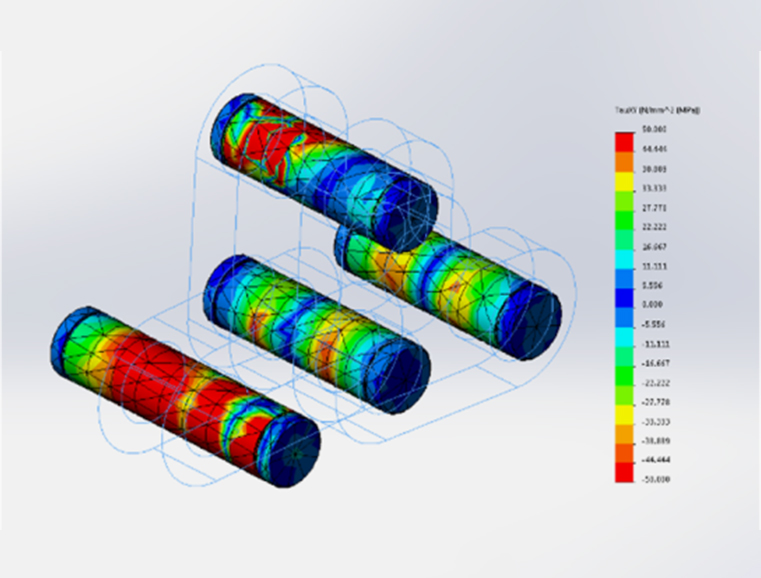

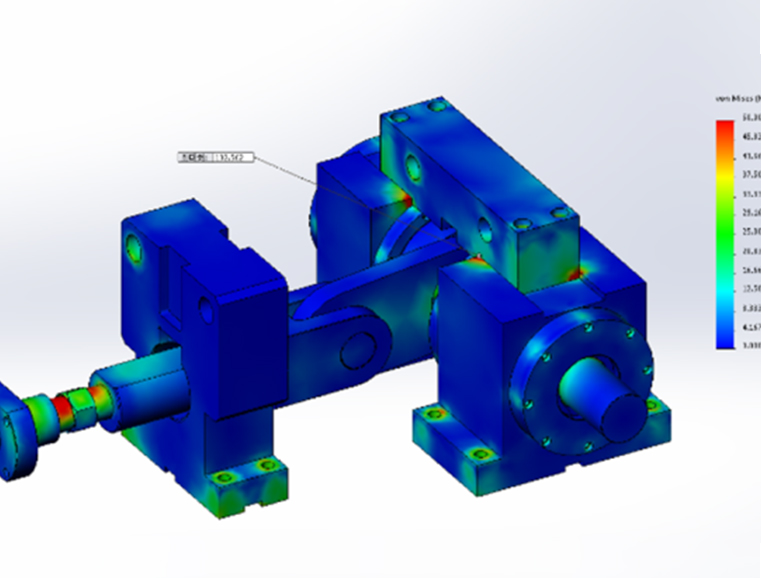

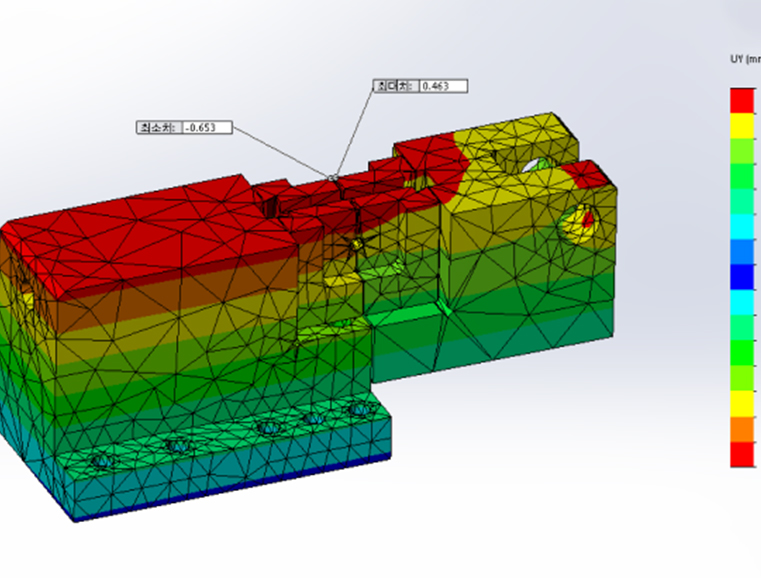

- Research on advanced bending, forming, and cutting technologies

- Study on automation and smart factory integration

- National R&D projects for technology innovation

- Patent development and registration activities

Research achievements

- Development and implementation of the 2020 Intelligent Root Process System Project (National Root Industry Promotion Center)

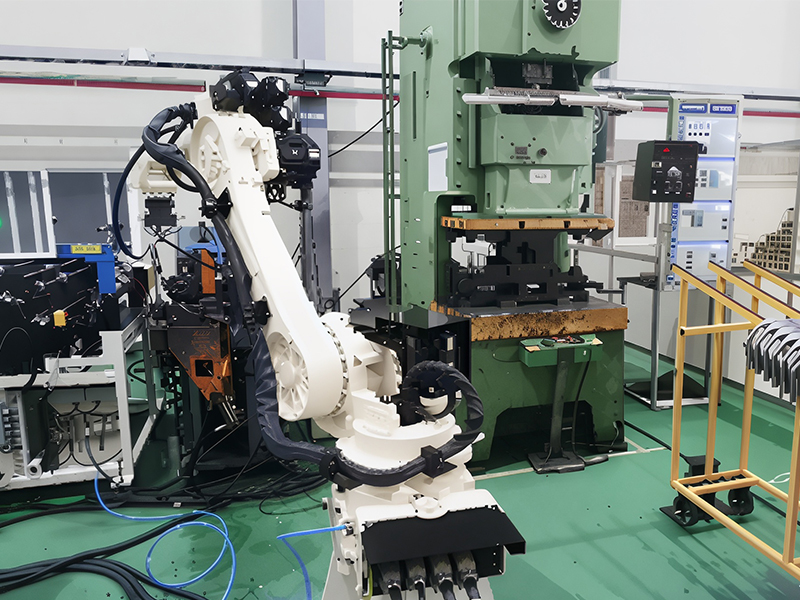

- Establishment of a robotic pipe frame processing system for automotive seat manufacturing

Research achievements

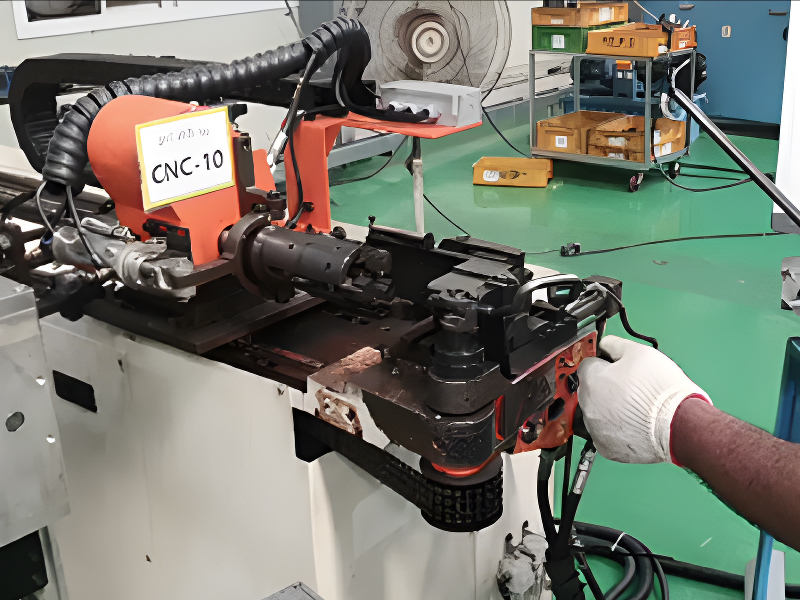

In 2017, ECO CNC carried out the SME Commercialization Technology Development Project under the Ministry of SMEs and Startups.

Through this initiative, the company successfully developed a large-scale Hyper CNC All-Servo Tube (Pipe) Bender.

Through this initiative, the company successfully developed a large-scale Hyper CNC All-Servo Tube (Pipe) Bender.

Additional Services

We Also Offer

We also offer specialized manufacturing and process innovation projects, including

- The 2016 Small and Medium Manufacturing Support Program

- The Process Innovation Project (Korea Robot Industry Promotion Agency)

- High-frequency heat treatment and robotic drilling fusion for press mold applications

- The Complex Process Innovation Project