COMPANY

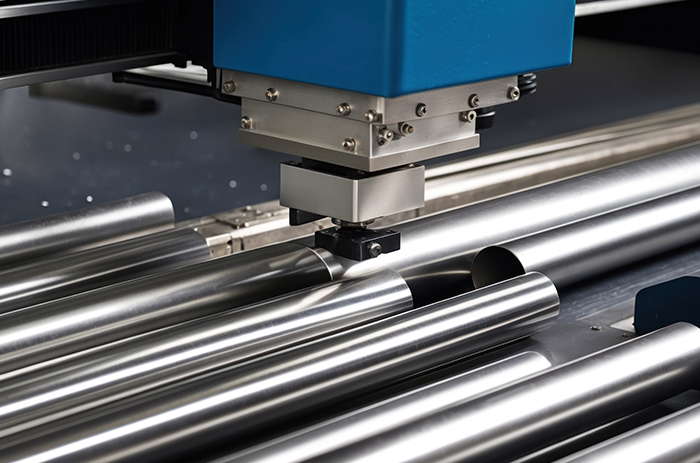

ECO CNC offers total solutions for automated lines involving pipes

ECO CNC

Machinery production

ECO CNC produces all types of machinery related to pipes including knife cutting machines and pipe forming machines

to sell both domestically and internationally.Meet high-efficiency and high-quality pipe bending with a high-speed, high-precision

CNC bending machine based on ECO’s many years of bending know-how.

Software Support

ECO CNC bending machines have the ability to connect to the internet, enabling constant software support and updates throughout the life of the machine. More importantly, this internet connection allows our technical engineers to remotely dial into the bending machine and help resolve any technical issues you may have. This 24-hour remote access enables any issue to be quickly and efficiently solved to get your production back up and running once more.

Customer Training

ECO CNC training team are always available to instruct and equip your workforce with the skills required to get the most out of your new ECO CNC machine.

Our training team have been to all four corners of the globe so no factory is too remote!

Our training packages cater for both the most experienced operators and apprentices with no prior knowledge. You can be assured that when the ECO CNC training team have done their job, all your operators will be capable and ready to utilise your new ECO CNC machine to its full potential.

Spare Parts

ECO CNC internal and external training team are always available to instruct and equip your workforce with the skills required to get the most out of your new ECO CNC machine.

Our training team have been to all four corners of the globe so no factory is too remote!

Our training packages cater for both the most experienced operators and apprentices with no prior knowledge. You can be assured that when the ECO CNC training team have done their job, all your operators will be capable and ready to utilise your new ECO CNC machine to its full potential.

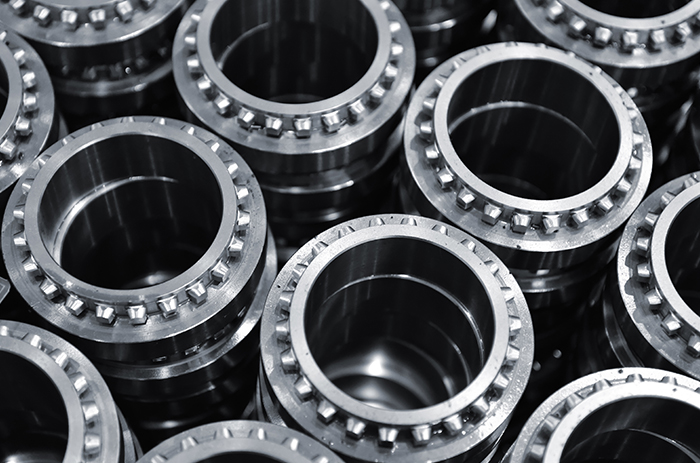

Tooling

ECOCNC’s in house tooling design and manufacture team deals with any application that requires forming, bending or pressing.

We specialise in custom applications and thrive on being able to deliver a solution where others cannot.

Because all of our research, design and manufacture is done under one roof, we offer a single point of contact, reduction in lead times, reduction in cost and most importantly a turnkey package from a single source. In addition to providing tooling for ECOCNC products we are also able to produce tooling for other machines.